In order to attract consumers, in recent years, merchants have put more and more efforts into cosmetic packaging. Various novel and exquisite packaging have emerged in an endless stream. Excellent outer packaging and bottle design have indeed become factors in the sales of products. In fact, the role of cosmetic packaging is not only to attract consumers, but also provide essential storage space and protection functions for the material body.

Cosmetic packaging Divided into two types: inner and outer materials The inner packaging material is in direct contact with the material body The form chosen is closely related to the product ingredients.

1. Common Cosmetic Inner Packaging Materials

Common cosmetic inner packaging materials include plastic bottles, glass bottles, plastic cosmetic tubes, etc. Different materials of inner packaging materials have different characteristics and are suitable for cosmetics with different textures and ingredients.

1). Plastic Bottle

Each plastic bottle is made of a variety of materials, including ABS (acrylonitrile-butadiene-styrene), PP (polypropylene), PE (polyethylene), PET (polyethylene terephthalate), AS ( Styrene-acrylonitrile copolymer), acrylic, etc. Among them, PP, PE, and PET are environmentally friendly materials and can be in direct contact with the contents; PP and PE are translucent, white in color, and can be made into various hardnesses; PET is transparent, light in weight, and soft in material.

2). Glass Bottle

Glass bottles are mainly used in cosmetics for smaller products such as creams, ointments, lotions, essences, and essential oils. According to the type of bottle mouth, glass bottles can be divided into wide-mouth bottles and narrow-mouth bottles. Wide-mouth bottles are mostly used for solid paste cosmetics such as facial creams and smear-type masks, while narrow-mouth bottles are generally used for aqueous and lotion cosmetics.

Glass bottles are generally used with caps, pump heads, or droppers to better ensure the cleanliness of the product. The body of the glass bottle can be frosted, spray-coated or silk-screened.

The advantage of glass bottles is low cost, but the disadvantage is that they are heavy and easy to break. Perfume products often use glass bottles to better prevent liquid evaporation and maintain the scent of the perfume.

3). Plastic Cosmetic Tube

According to the number of layers, cosmetic tubes can be divided into single layer, double layer, and five layers; according to the material, they can be divided into plastic cosmetic tubes and metal cosmetic tubes. The most common one is plastic cosmetic tube, which is the packaging used for ordinary facial cleanser. PE plastic is generally used.

The cosmetic tube packaging has good airtightness, which can isolate the outside air and prevent the contents from leaking. The anti-penetration capabilities of cosmetic tubes with different layers are different. The hose is generally equipped with a rotating cap or a flip cap, and the tube body can be processed by silk screen printing and other processes.

2. Special Ingredients Require Special Packaging

Some cosmetics require special packaging due to their special ingredients to ensure the activity of the ingredients. Dark glass bottles, vacuum pumps, metal cosmetic hoses, and ampoules are commonly used special packaging.

1). Dark Glass Bottle

After the photosensitive ingredients in cosmetics are oxidized by ultraviolet rays, they may not only lose their activity and efficacy, but may even cause sensitization and toxicity. For example, ascorbic acid and ferulic acid are easily photolyzed and oxidized, and vitamin A alcohols and their derivatives, and furanocoumarins are photosensitive and phototoxic. In order to prevent such ingredients from being oxidized by ultraviolet light, the packaging must be protected from light. Dark opaque glass bottles are generally used as packaging materials, and dark brown glass bottles are the most common. To ensure ease of use and product hygiene, dark glass bottles are often used with droppers.

Cosmetic brands that focus on functional ingredients often use dark glass bottles to ensure that the ingredients are effective.

It should be noted that although dark glass bottles are used to avoid light, it does not rule out the use of dark glass bottles purely for traditional or appearance reasons. Some cosmetic ingredients do not contain photosensitive ingredients, but brands take into account the traditional use of dark glass bottles and droppers in medicines and will also use the above packaging in order to attract consumers.

2). Airless Pump

Although dark glass bottles have good light-shielding properties, they can only completely isolate the air before use. They are not suitable for ingredients that require higher air isolation (such as ubiquinone and ascorbic acid for antioxidants), as well as those that are easily oxidized. Oil ingredients (such as shea butter), etc.

If the product ingredients have higher requirements on the airtightness of the packaging, a vacuum pump can be used. Airless Pumps generally use AS materials, whose significant advantage is that they can well isolate the contents from the outside air. There is a piston at the bottom of the bottle of the airless pump. When the pump head is pressed, the piston at the bottom of the bottle moves upward, the contents flow out, the bottle space is reduced, and air will not enter.

3). Metal Cosmetic Tube

Since the airless pump is made of plastic, it has poor light-shielding properties. If the product ingredients have high requirements for both light-shielding and air isolation (such as vitamin A alcohol substances), metal cosmetic tubes need to be used. High-concentration vitamin A alcohol products are usually stored in aluminum cosmetic tubes. Compared with plastic materials, aluminum cosmetic tubes have stronger airtightness and can block light and moisture, which can better protect the activity of the contents.

4). Ampoule

Ampoules are one of the popular inner packaging materials in the cosmetics industry in recent years, and their airtightness and safety are remarkable. The idea of ampoules in the cosmetics industry came from ampoules in the medical industry. Ampoules can store active ingredients in an airtight manner and are single-use. They can isolate air and pollutants and ensure product hygiene. In addition, glass ampoules can be made in dark colors to provide good light protection. Products with aseptic filling and single-use ampoules do not have preservatives added, providing a new option for consumers with severely sensitive skin or those who are unwilling to use products containing preservatives.

3. Store Cosmetics According To Ingredient Requirements

Although the inner packaging can help maintain the stability of cosmetics and the activity of functional ingredients, after purchasing the product, consumers need to save it according to the instructions to further extend the shelf life of the product. Cosmetics with special needs will be marked on the outer packaging if they need to be kept away from direct sunlight or placed in a dry place.

Many active ingredients in cosmetics are not very stable, and the properties of the products are prone to change under high or low temperature conditions. Active substances such as vitamin A, peptides, enzymes, etc. may change color and become ineffective at high temperatures, so they are suitable for low-temperature storage. However, just because the active ingredient is unstable does not mean the product is unstable. Before the product is produced, the formulator has taken various situations into consideration and ensured the stability of the product through formula, packaging materials, etc. So looking at ingredients in isolation without considering the overall formula and taking it upon yourself to refrigerate or heat a product can be counterproductive.

If the room temperature is too low, some water-based or pure oil cosmetics may freeze or crystallize. If the emulsifier content in the formula is very low, stratification will occur at low temperatures. In this case, the product can be heated appropriately or stored at the appropriate temperature.

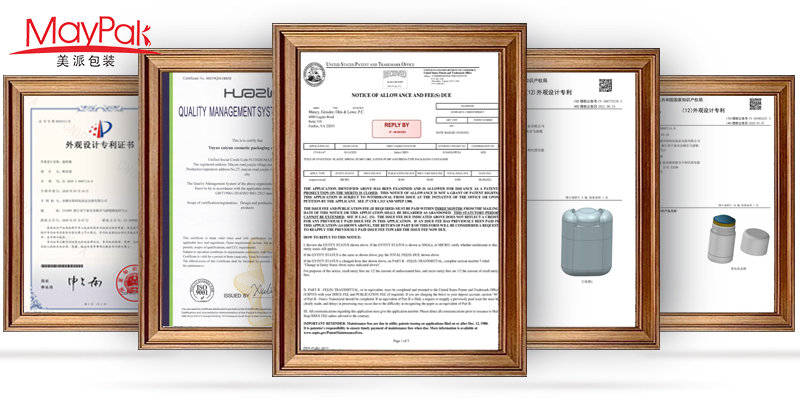

*Maypak packaging is Cosmetic Packaging Manufacturer and has been focusing on Cosmetic Packagings for more than 18 years and was established in 2006,the company enjoys a good reputation at home and abroad. If you have any questions about lipstick tubes, please contact us.

Copyright © 2024 BOTTLE - aivideo8.com All Rights Reserved.