Environmentally friendly packaging refers to a packaging method that is environmentally friendly and sustainable. In today's society, people have an increasing demand for environmentally friendly packaging because it can reduce negative impacts on the environment and promote sustainable development. Some common environmentally friendly packaging methods will be introduced below.

1. Paper Packaging is a very common way of environmentally friendly packaging. Paper packaging can be made from recyclable paper materials and can be recycled to reduce the consumption of forest resources. Compared with plastic packaging, paper packaging can effectively reduce carbon emissions and reduce pollution to the atmosphere and water bodies.

2. Biodegradable Packaging is also an environmentally friendly packaging method. Biodegradable packaging refers to packaging materials that can naturally decompose into organic matter. Common biodegradable packaging materials include corn starch, cellulose, etc. These materials can be decomposed by microorganisms in the natural environment and eventually converted into organic fertilizers. Compared with plastic packaging, biodegradable packaging has a smaller impact on the environment and reduces the accumulation of plastic waste.

3. Recyclable Packaging is also an environmentally friendly packaging method. Recyclable packaging materials include glass, metal, etc. These materials can be recycled and reused, reducing resource consumption. Compared with single-use packaging materials, recyclable packaging can reduce the generation of waste and reduce the burden on the environment.

4. Reducing packaging is also an environmentally friendly approach. Some products use too much packaging materials in the packaging process, which not only increases costs but also wastes resources. By reducing the use of packaging, you can reduce costs, reduce resource consumption, and be more environmentally friendly.

5. Using renewable energy to produce packaging materials is also an environmentally friendly way to package. Fossil fuels are often used in the production process of traditional packaging materials, resulting in large amounts of greenhouse gas emissions. The use of renewable energy, such as solar energy, wind energy, etc., can reduce dependence on fossil fuels, reduce carbon emissions, and be more environmentally friendly.

Environmentally friendly packaging is an environmentally friendly and sustainable packaging method. Paper packaging, biodegradable packaging, recyclable packaging, reducing packaging usage and using renewable energy to produce packaging materials are all common ways of environmentally friendly packaging. Actively advocate environmentally friendly packaging, reduce negative impacts on the environment, and contribute to sustainable development.

Environmentally Friendly and Renewable Mission

1. PCR Products

The full name of PCR is Post-Consumer Recycled material, which recycles recycled materials such as PET PP PE ABS and then processes them into plastic raw materials used to make new packaging materials. Waste packaging is given a second life.

Disadvantages: It cannot be used for packaging with relatively high hygiene marks, such as medicines, etc. Surface spots, black spots and other impurities cannot be avoided.

2. Carbon Black Free Products

Carbon black is used for black and titanium dioxide (TiO2) is used for white. Products with carbon black do not reflect light enough and are difficult to break down. Composite inorganic colored pigments (CICP) and manganese ferrites (the latter are much more cost-effective) are excellent alternatives to carbon black, thanks to their properties - as they reflect infrared light Imported copper chrome black It is an inorganic toner that can achieve the effect of carbon black

Composite inorganic pigments (CICP pigments) formed by high-temperature calcination at 800-1300℃ have excellent chemical stability and environmental protection. It has the characteristics of retaining pigments and has good compatibility with various resins and solvents. Weather-resistant and sun-resistant, the color will not change significantly for 30 years outdoors. Chemical, no migration, no bleeding, acid and alkali resistance, easy to disperse, high temperature resistance 800°C-1200°C.

Widely used, it can be used in architectural coatings, powder coatings, coil coatings, reflective insulation coatings, military camouflage coatings, ceramics, Glass, enamel, fiber, leather, painting, nail art, general plastics, fluoroplastics, special engineering plastics, etc., as well as some Fields with high environmental performance requirements, such as food packaging containers, tableware, children's toys, etc.

3. PLA Raw Materials

PLA's scientific name is polylactic acid, commonly known as corn plastic. It is a fully biodegradable and environmentally friendly material. It has excellent performance, not only excellent impact toughness, but also wear resistance, wide operating temperature range, good dimensional stability, excellent electrical insulation, and non-toxicity. Wheat straw plastic is a new green and environmentally friendly composite material made of straw, rice husk, cellulose and other natural plant fibers and polymer resin through a special process. It has similar properties to ordinary thermoplastic plastics and can be molded by injection molding. Decomposes on its own in nature.

Polylactic acid (PLA) is preferred. PLA has excellent biodegradability. It can be 100% degraded by microorganisms in the soil within one year after being discarded, producing dioxide Carbon and water, no pollution to the environment. Truly "from nature, return to nature"!

4. Marine Biomaterial PDA

The Chinese name of DPA is marine biodegradable masterbatch. It is a new type of fully biodegradable material produced by using marine shellfish shell waste as the main raw material and processed according to a professional active formula. This degradable material has achieved a major historical technological breakthrough. The product produced by mixing DPA and traditional plastic materials in proportion can achieve full biodegradation in the soil environment.

5. Marine biomass OBP

OBP, the full name is: Ocean Bound Plastic Certification, usually also called ocean plastic certification. In the industry, OBP is also called new ocean recycling material. OBP is a kind of plastic waste that is not properly managed and is abandoned in the environment. There it is transported to the ocean by rain, wind, tides, rivers, floods

6. Plant-based PET-BIO

Plant Bottle's plastic bottles use patented technology to convert natural sugars in plants into raw materials for PET. This new bottle is no different from traditional petroleum-based PET in appearance, function and regeneration.

Coca-Cola launches world's first PET bottle made entirely from plant sources at Expo Milan

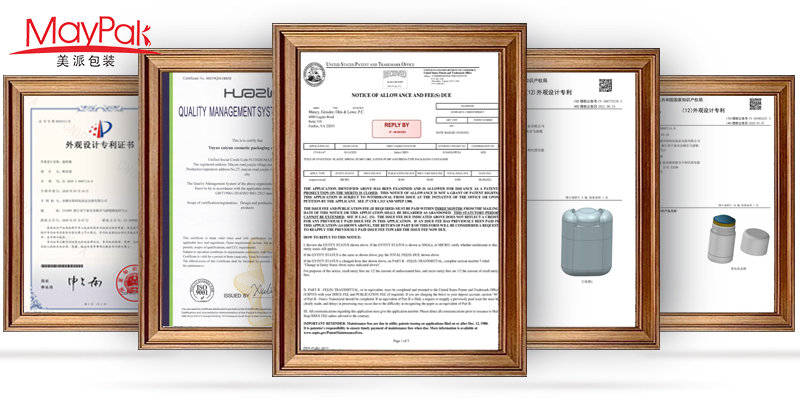

*Maypak packaging is Environmentally Friendly Packaging Manufacturer and has been focusing on Environmentally Friendly Packagings for more than 17 years and was established in 2006,the company enjoys a good reputation at home and abroad. If you have any questions about lipstick tubes, please contact us.

Copyright © 2024 BOTTLE - aivideo8.com All Rights Reserved.